Jordan First Post

Jordan’s First Post

Biography

Jordan is a PhD student in Mechanical Engineering at Georgia Tech in the Materials Informatics for Engineering Design (MINED) Research Group. Jordan completed his Master’s at Drexel University and Bachelor’s from Temple University both in Mechanical Engineering. The focus of his thesis work is developing protocols to accurately characterize length scale effects in titanium alloys including the effects of interfaces using spherical instrumented indentation.

More info on Jordan at LinkedIn

Project Responsibilities

Spherical Nanoindentation

Recent spherical nanoindentation protocols have proven valuable for characterizing the local mechanical response of different materials systems in the form of indentation stress-strain curves [1-4]. For Ti alloys this is the grain scale response which depends on the phase (hcp, bcc) and crystal orientation. Indentation has the advantage of being cheap and high-throughput compared to other grain scale mechanical testing methods. Grain scale mechanical property measurements are needed to accurately capture the grain scale plastic anisotropy in Ti alloys to improve the accuracy of crystal plasticity simulations for predicting fatigue and failure.

Spherical Micro/Macro/Meso Indentation

Grain scale indentation measurements do not account for the effect of grain and phase boundaries or microtextures. Indentation measurements at the meso scale probe multiple phases and grains at one time to establish length scale effects going from single grains and single phases all the way to bulk properties. The characterization of these length scale effects are needed to properly implement crystal plasticity models calibrated to grain scale measurements.

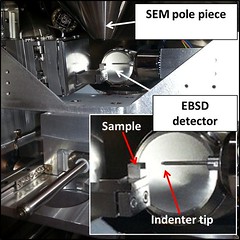

InSEM Nanoindentation

Interface modeling is an area of ongoing research which is limited by the lack of available experimental datasets for information and calibration. With a unique setup of a wedge indenter inside an SEM, single interfaces can be probed while simultaneously characterizing the deformation in the indentation zone using electron backscatter diffraction (EBSD). These experiments provide a rich amount of information for improving interface modeling, particularly the alpha-beta interface in Ti alloys.

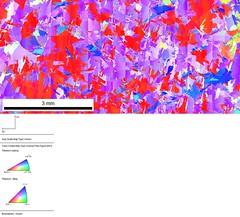

Structure Characterization for WSVEs

Large electron backscatter diffraction (EBSD) data sets will be collected on orthogonal sections for generating representative volume elements (RVEs) for crystal plasticity finite element simulations. The spatial statistics (2-point) of the microstructure will be used to generate the RVE rather than predetermined feature measurements and distributions which will provide a more statistically meaningful RVE or a set of weighted statistically meaningful RVEs (WSVEs) [5-6].

Research Articles

- Kalidindi, S.R. and S. Pathak, Determination of the effective zero-point and the extraction of spherical nanoindentation stress-strain curves. Acta Materialia, 2008. 56(14): p. 3523-3532.

- Kalidindi, S.R., S. Pathak, and D. Stojakovic, Measurement of the local mechanical properties in polycrystalline samples using spherical nanoindentation and orientation imaging microscopy. Acta Materialia, 2009. 57(10): p. 3020-3028.

- Pathak, S., et al., Studying grain boundary regions in polycrystalline materials using spherical nano-indentation and orientation imaging microscopy. Journal of Materials Science, 2012. 47(2): p. 815-823.

- Pathak, S., et al., Assessment of lamellar level properties in mouse bone utilizing a novel spherical nanoindentation data analysis method. Journal of the Mechanical Behavior of Biomedical Materials, 2012. 13: p. 102-117.

- Niezgoda, S.R., et al., Optimized structure based representative volume element sets reflecting the ensemble-averaged 2-point statistics. Acta Materialia, 2010. 58(13): p. 4432-4445.

- Qidwai, S.M., et al., Estimating the response of polycrystalline materials using sets of weighted statistical volume elements. Acta Materialia, 2012. 60(13–14): p. 5284-5299.